VCST develops 2-speed offset gearbox for electric delivery trucks

21 April, 2022

For the last two years, VCST has increased its focus on powertrain electrification. It began with the award of a prestigious project for the manufacturing and supply of the compound pinion gears of a 1-speed planetary Primary Drive Unit for one of the best-selling all-electric SUVs, launched in 2019. Besides pure component (gear) manufacturing, VCST also invested in the development of complete gearboxes or ‘e-drives’ for electric vehicles. Currently, VCST can present a comprehensive product line-up of mainly 2-speed transmissions. As of today, 2-speed e-drives still might be considered as ‘niche’ in a market that is dominated by 1-speeds. Nevertheless, VCST truly believes in the potential of multispeed as performance (torque, speed, range) requirements are getting higher and applications more diverse. One of our latest multispeed e-drive projects has been developed with our Mexican partner Questum (a company of Quimmco group) and its mobility business unit.

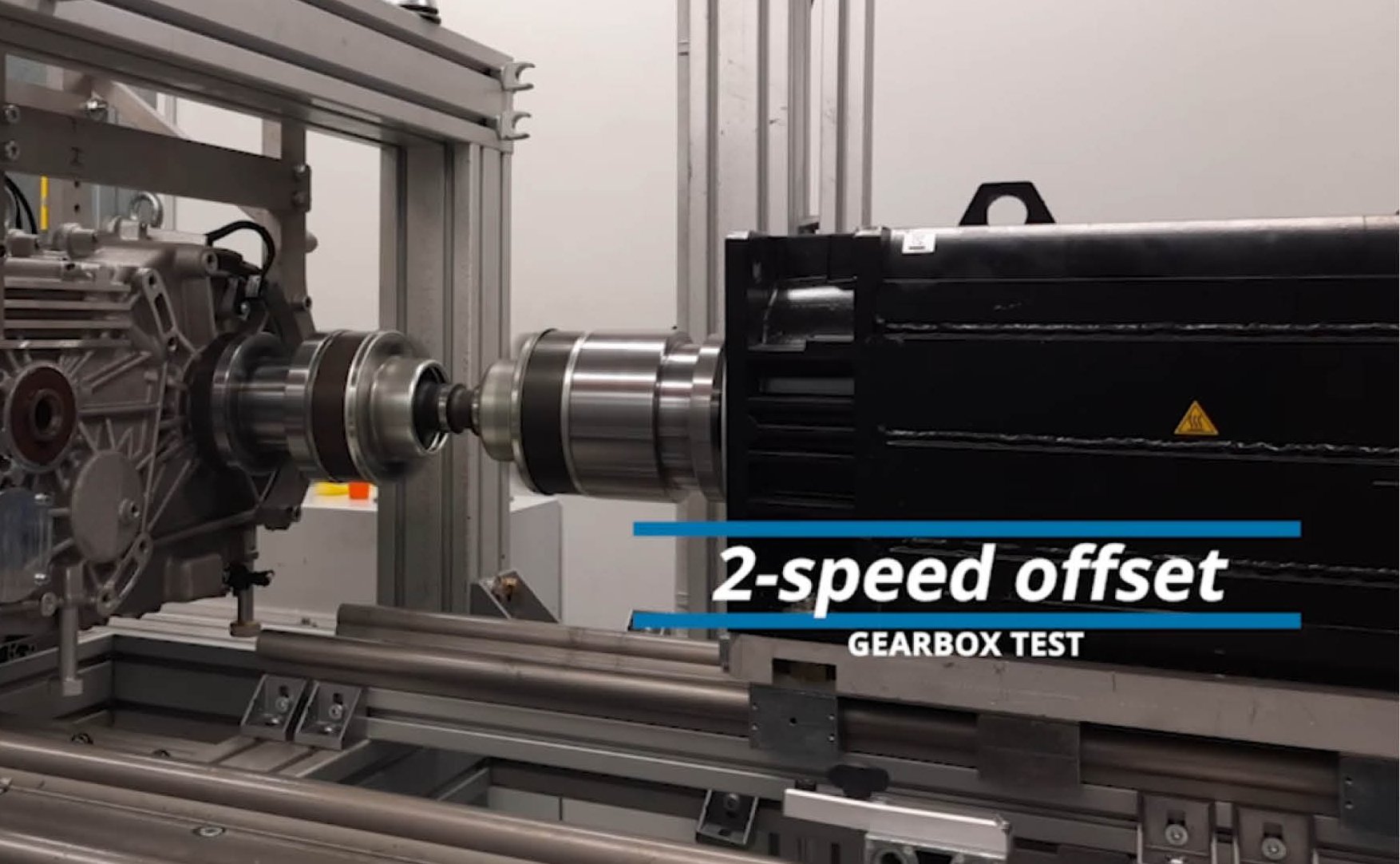

More specifically, VCST has been developing a 2-speed offset gearbox, meant for electric delivery trucks. The gearbox we have developed reaches significant levels of output torque and exceeds the levels that you can find in e-vehicles on the market today.

2-speed gearbox for electric commercial vehicles & trucks

Today, electrified delivery truck fleets often don’t have a gearbox, but use a direct drive system. The downside to these direct drive motors, is that they are much heavier and quite expensive. In addition, direct drive systems in general don’t perform as well as systems that use our gearbox.

By using a downsized motor in combination with our 2-speed gearbox, Questum will be able to reduce the costs, all while having the benefits of improved performances. “We are pleased to be a partner of VCST to bring/test this solution to meet the needs of the Mexican market” said Osvaldo Gallegos, Quimmco CCO, and Questum Mobility Business Unit Leader.

Currently, our gearbox reaches up to 5,000 Nm, but thanks to a new optimized housing that will be used in the future, we are already targeting to reach more than 9,000 Nm. This will make our gearbox even more powerful than it is today.

Multiple features are integrated, such as a new external cooling system that assures that all friction losses are released easily, the 2-gear shifting system, an electric oil pump that redistributes oil to the different bearings and gears and a temperature sensor, all controlled by our TCU.

Since we deliver the full EDU, including the motor and inverter, we have to make sure our gearbox is optimized and integrated in the best way possible. The installation of input speed and output speed sensors also makes the gearbox an autonomous product from a control perspective, as the control relies completely on these sensors. This allows us to have a second-by-second view of the real situation of the shifting mechanism.

Currently, the gearboxes are on the test rig for final validation. After that, the units will be shipped to Questum in Monterrey, Mexico for integration into the first vehicles. It will be the first electric vehicles with VCST 2-speed technology inside on Mexican roads.

We are very excited to help shape the future of the automotive industry and are looking forward to see where our projects will lead us next.