Development

Product development starts with the customer requirements or the solution needed: the load or torque that is required, the necessary rational speed and gear ratio. Based upon these requirements, we use various applications to come to a solution for the required gears. With calculation software we design the specifications of the gears. We have developed in-house software for the macro-geometry for the gears and use KissSoft for the micro-geometry. We consequently know the macro and micro geometry of the gears, the gear-teeth contact ratio and teeth safety factors for bending and pitting. We prepare the drawings and CAM-models of the required solution.

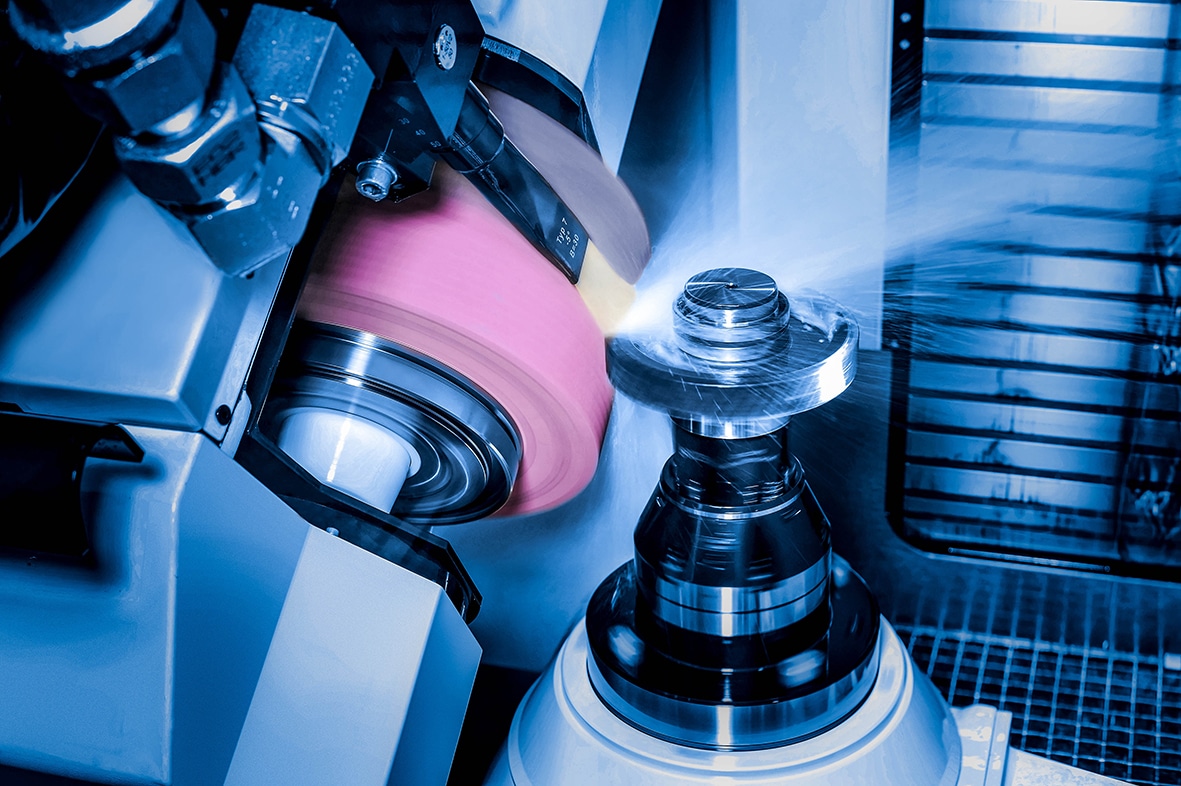

Prototyping

After this development phase in our R&D department, our protoshop starts making prototypes of the gears. Our protoshop is a lean organization that functions independently of our production facilities. It has its own machines, measuring equipment and raw materials stock. This enables the protoshop department to keep its own schedule and continue prototyping even when production is full. Our protoshop has a 5-axis machine with advanced technology that can make multiple variations. Our years of experience and the improvements we have made over the years allow us to quickly respond to questions and offer fast delivery of the prototypes.

Prototyping

NVH optimisation

As many of our customers were facing issues with rattle and whine noises, our organization has developed & manufactured several patented technologies to address these problems. So far, VCST has created over 25 patents. We keep developing solutions to constantly improve technology in response to our customers’ questions and demands. We have several patented scissor-gear designs to eliminate rattle noise caused by colliding gear teeth or impulses caused by shocks between teeth, for example. Whine noise caused by excitation or high frequencies are reduced thanks to advanced manufacturing processes and in-house tooth-shape deviation analysis. Several other patents are under development. These are both process-related and gear-design related patents that will further allow us to reduce noise and deliver top class products.

Validation

We design our gears to have an infinite life. To ensure our solutions are top notch, they are all tested in-house. We have both destructive testing facilities, which test material fatigue strength, and non-destructive testing equipment for NVH-measurement.

As regards, material fatigue strength, we test durability, pitting and also teeth bending.

Validation

-

Development

-

Prototyping

-

NVH optimisation

-

Validation