VCST Reichenbach visits Continental

14 February, 2020

Working for VCST is very rewarding. However, because all the products we make are located at the heart of various applications, it is quite difficult see them in action. In order to give our employees a clear example of where our products are used, a mixed group of 35 VCST Reichenbach employees visited Continental Teves in Frankfurt, our biggest customer.

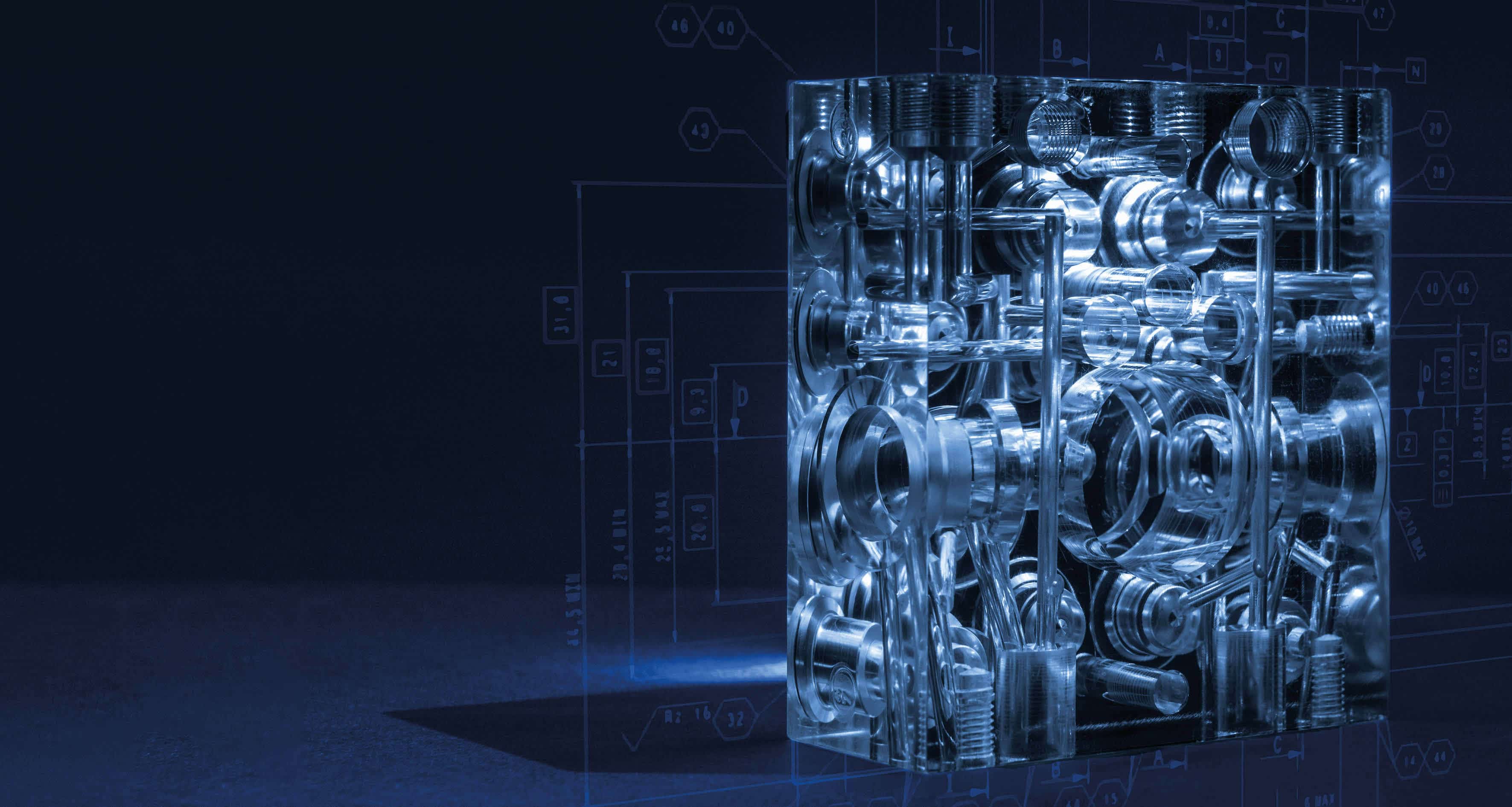

The aluminum valve blocks made by VCST Reichenbach serve as components for safety parts in cars. They are fitted into hydraulic break systems which control ABS, ESP and many more safety and stability functions. Since these functions are integrated in many different cars, our aluminium valve blocks have a profound effect on road safety. They have to operate to a high degree of precision on a daily basis while our customers naturally demand zero defects.

The aluminium valve block, as made by VCST Reichenbach:

At the beginning of our visit, we were given an introduction on the Continental plant in Frankfurt as well as more ample details on various valve blocks and break systems. In order to highlight the importance and increase sensitivity about the high quality VCST delivers on a daily basis, two videos were shown. The videos showed the difference between the behaviour of a car that had safety functions like ABS and ESP and a car that didn’t. The difference the safety functions, and ultimately the VCST components, made, helped to incentivise us even more.

People are never to old to learn. Therefore, the people at Continental went on to explain the critical and safety relevant characteristics of the systems our valve block is installed in. As a means to aid our sensitivity, there was also an explanation on why our valve block is so important. Indeed, it was explained that without the safety functions, and ultimately the VCST valve blocks, modern cars would behave much more unpredictably in a crash. Learning in more detail about the eventual usage of our own product turned out to be an enlightening experience.

Afterwards came perhaps the most interesting part of the day. During a tour of the Continental plant, we were shown how our high runner product is assembled. Learning about what components our valve blocks are fitted into and what is attached to them proved to be valuable experience. Indeed, it provided all of us with a clear determination to keep investing maximum effort in the quality we deliver. The perfect reward, then, for VCST Reichenbach’s hard work came in the official recognition of the Continental quality representatives.