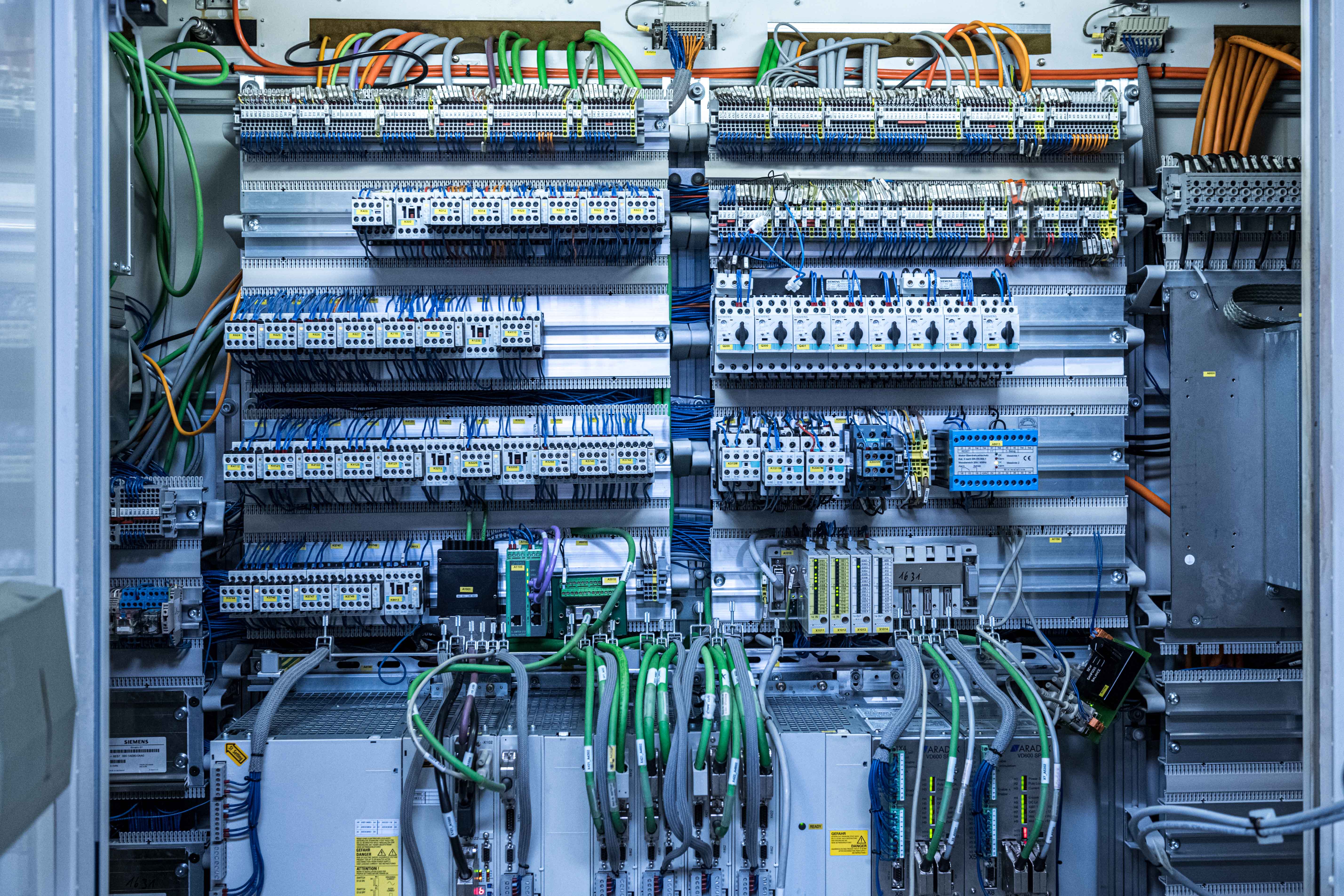

Smart factory

Our customers can rely on more flexibility and a faster response time based on real-time data collection thanks to our smart factory digital solutions. We are in the process of connecting suppliers, people, devices, machines and customers in systems and smart applications, resulting in more reliable and integrated processes, thus higher quality. This enables us to grow our capabilities and ensure full traceability throughout the whole supply chain. Our goal is to reach zero complaints from our customers. Through digital manufacturing, we want to deliver the highest quality by implementing a smart and digital way of working. This makes us also an attractive employer for skilled and talented future employees.

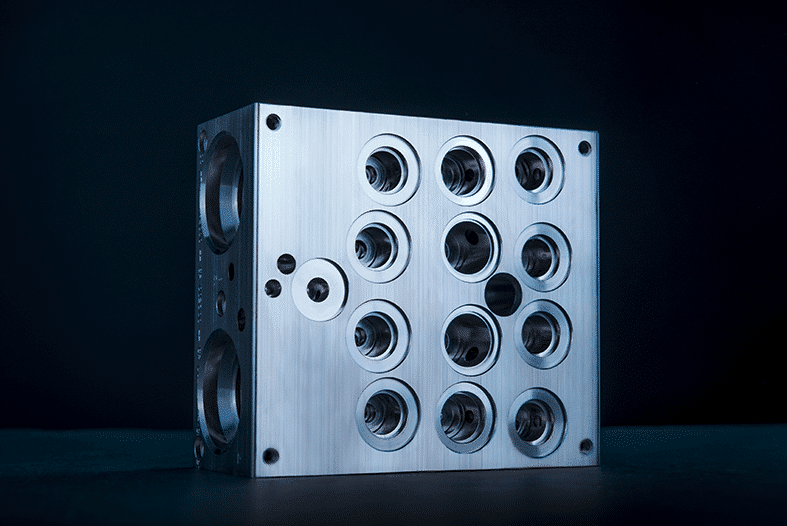

Skiving

The rapid advancement of vehicle electrification creates serious challenges in the gearing industry. The electrical motor inside the hybrid drive or full eletric drive rotates at very high rpm. This high rotation speed needs to be transferred to the vehicle wheels, which rotate at a lower speed. Since weight and place are important, the designs for these transmissions are compact, lightweight and power dense. This leads to new designs for gearings and shafts, planetary gear sets, special stepped pinion gears, special thin ring gears and shafts with multiple gearings. Standard hobbing and generative gear grinding cannot be used to produce these gearings because of collision. We have therefore invested in new skiving machinery to enable us to meet the new challenges that battery electric vehicles and hybrid electric vehicles bring.

Skiving

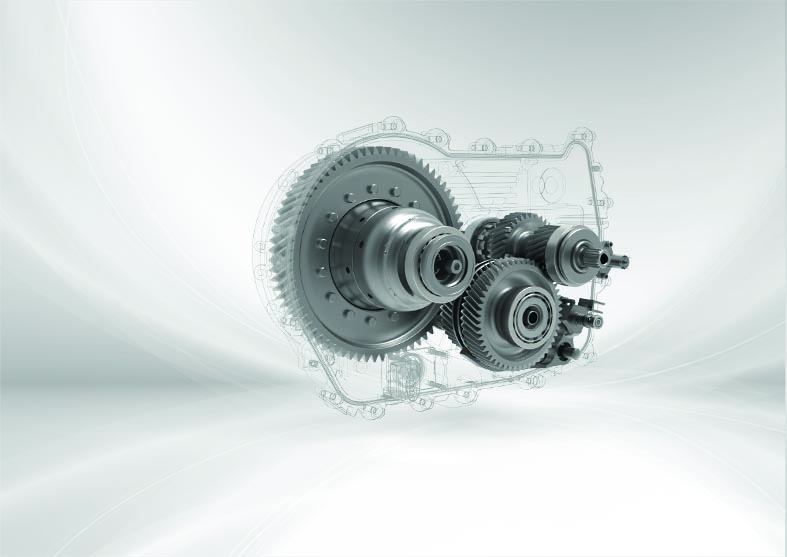

Power gear honing

To achieve robust gears that are more resistant to wear and micro pitting under high loads, gear honing comes into play. Gear honing is also relevant when noise optimization is very important, as is the case in the construction of electric & hybrid engines. With the growth of electric and hybrid technology, noise reduction is important as we want the driver to hear the engine, not the noise produced by gears. Gear honing ensures quiter gear shifting.

Gear inspection techniques

We are using all common gear inspection techniques such as gear charting, double and single flank testing, but also advanced techniques like gear flank waviness inspection and single flank NVH analysis.

Gear inspection techniques

-

Smart factory

-

Skiving

-

Power gear honing

-

Gear inspection

Our Solutions

Aluminium brake components providing safety and comfor

Transmissions and shafts for all vehicles

Our factories are equipped with furnaces and auxiliary treatment installations for our own products or those of external parties

We are your one stop solution for engine gear-components

Discover our full eDrive line-up for a variety of vehicles