The origin of our valve blocks

29 March, 2024

In the ever-changing world of technology, you never know where groundbreaking advancements might come from. And in the case of VCST, a top-notch supplier of automotive parts like valve blocks, their origins can be traced back to an unexpected connection with IBM Mainframe computers. It's pretty fascinating!

Back to the future

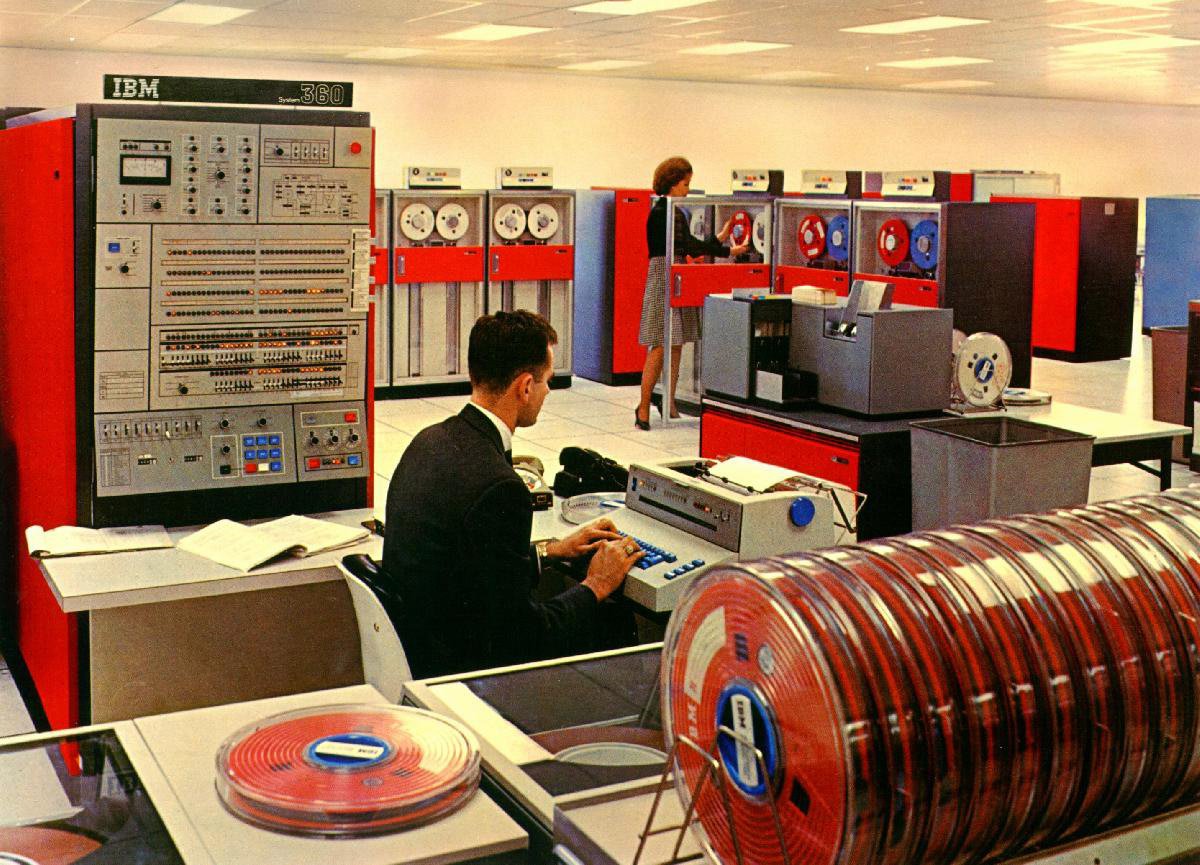

Let's take a trip down memory lane to the late 1980s and 1990s, when those giant IBM Mainframes ruled the computing world. These massive machines, with their flashy lights and gigantic square structures, were the epitome of cutting-edge technology back in the day. Sure, our sleek and compact devices have stolen the spotlight now, but we shouldn't forget the important role these Mainframes played in shaping our tech landscape. So let's give credit where credit is due!

In the midst of this era, VCST went on this really cool journey that got it all tangled up with IBM Mainframes. It was back in 1989 when VCST decided to take on the challenge of making base plates for IBM.

The base plate, a critical component in the Mainframe system, was meticulously crafted through a multi-step process. Firstly, an inox insert, derived from a stainless steel forged piece, underwent precision machining to serve as a bearing bushing for the disk drive. Subsequently, this insert was encased within a substantial aluminum housing through a casting process. Following this, a crucial intermediate step involving deep cooling was employed to relieve any residual stresses within the material. Finally, the aluminum components underwent precision machining on CNC machines, ensuring the utmost accuracy and purity.

More specifically, base plates were responsible for making sure those discs spun around at lightning speed. The slightest mistake in getting them just right could cause some major problems. We're talking disaster territory here! Even the tiniest bit of friction could mess everything up and put those discs' integrity at risk.

The foundation of our valve block know-how

To meet IBM's crazy high standards, VCST used their precision engineering skills to make these base plates with extreme care. We looked at every little detail – the dimensions, the shape, even the materials used – to make sure everything was top-notch. And guess what? It paid off big time. The end result was a masterpiece that showed just how dedicated VCST is to quality and precision. These base plates fit into IBM Mainframes like they were made for each other, making those machines run like a well-oiled machine. Efficiency and reliability? Check and check!

The IBM Base Plates was VCST's first try at making aluminum parts for VCST. It was a big step that helped VCST become skilled in precision engineering with aluminum. This marked the start of VCST's journey to becoming experts in valve block development, thanks to the dedicated production area that was developed by the gained the knowledge and skills obtained by this project.

Fast forward to the present day, and VCST is a prominent player in the automotive industry. We are all about quality parts and precision in all our products, including our valve blocks. They show off VCST's long-standing legacy and their excellent skills in precision engineering.

Just as the base plates formed the backbone of IBM Mainframes, VCST's valve blocks serve as the cornerstone of automotive brake systems, ensuring optimal performance, efficiency, and reliability. With a heritage deeply rooted in the era of IBM Mainframes, VCST continues to push the boundaries of engineering excellence, driving innovation forward and shaping the future of automotive technology.