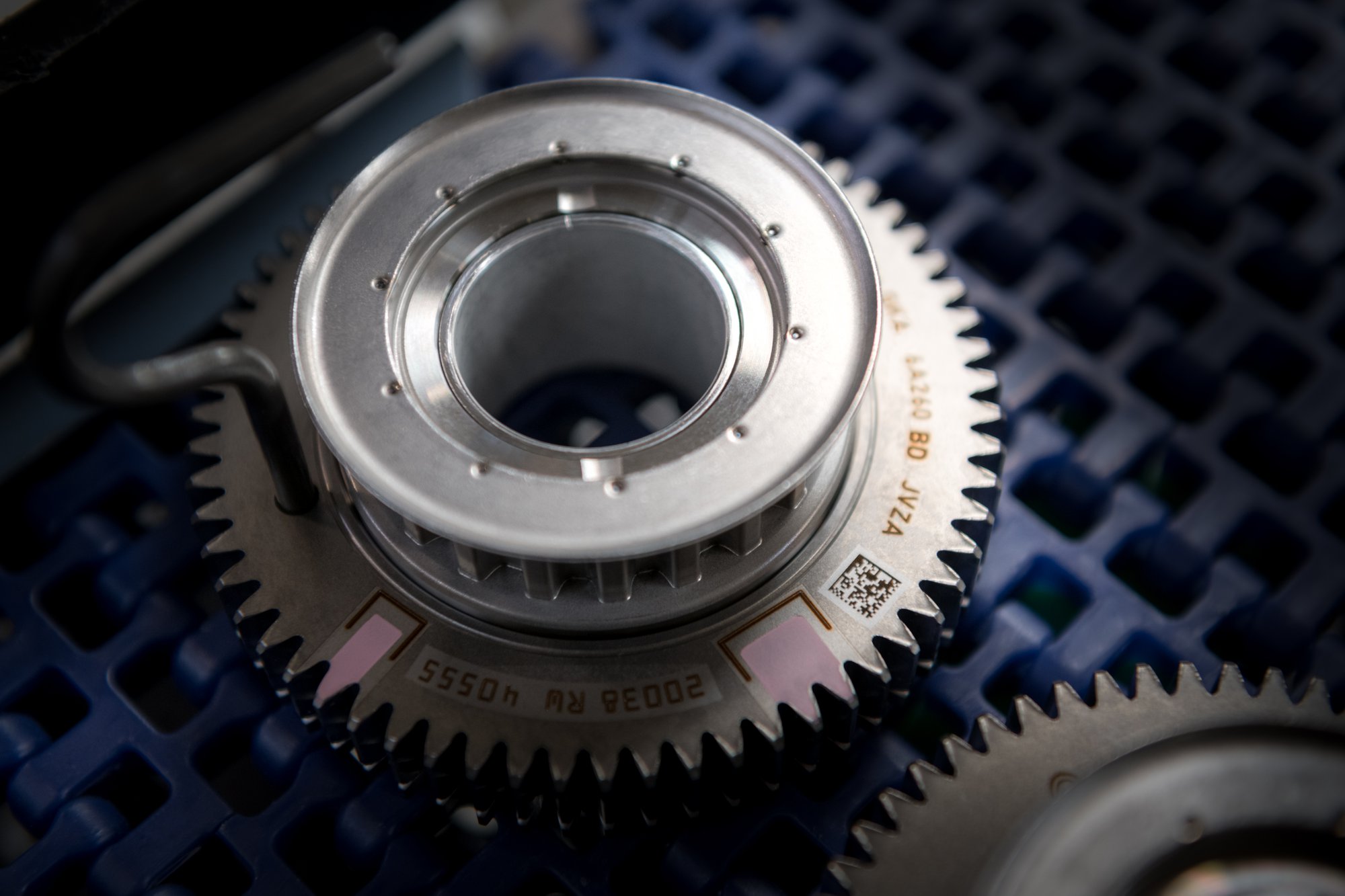

Special focus: VCST’s patented split idler gear

15 September, 2022

Today, the automotive sector is shifting to a full focus on electrification. With ambitious engineering and more and more electric cars appearing on the roads, we’re well on our way to an electric and green future. However, 2050 (the year by which the EU wants to have transport emissions 90% reduced) is a still a long way and we can’t neglect the quality and performance of our traditional cars.

While VCST is making big steps in becoming a world class supplier of electric drive solutions, we have been a world class supplier for conventional cars since decades. In that time, we have supplied a lot of excellent high-quality products and solutions for a variety of premium car manufacturers. One that stands out and we will always be proud of, is our split idler gear.

What is an idler gear?

Idler gears are placed between a driving and a driven gear to transfer motion without change of direction or gear ratio.

This specific split idler gears integrates multiple functions:

- A main gear to transfer torque to a driven gear

- A bias gear to eliminate noise

- A pulley to transfer torque to a belt drive

Each part has to be manufactured with high precision and close attention to detail. This is because the split idler gear is in constant contact with the crank gear and the FIP gear (which is also manufactured by VCST).

Quiet drives

Ever heard a rattle noise when standing at a red light? Well, that’s that’s what our split idler gear is able to resolve. In our patented split idler gear, the bias gear is in constant contact with its counterpart. The spring torque of the bias gear is extremely important for noise reduction.

If your torque is too low, rattle noise emerges. If your torque is too high, that will result in gear whine noise. Both noises are criteria on an engine level and are tested on a test rig once the engine is ready. The right torque results in an engine with optimal noise.

In other words, the bias gear in our split idler gears will determine if you can enjoy a quiet drive in the morning to work or go for a drive at night when you want to enjoy your beloved car.

Today, we offer three variants of our split bias gears with different torques to ensure the best solution for any type of engine.

Position is key

As may have become clear, accurate manufacturing is key to guarantee the best results. To make sure our biased gears are positioned perfectly against the main gear, a pin is installed right after the bias and main gear are assembled. This allows us to set the torque very precisely.

Once the split idler gear is installed, the pin is pulled out. This allows the split idler gear to place itself perfectly against the counterpart. As a result, rattle noise levels in the engine are reduced drastically.

Our split idler gear are one example of how VCST has been an innovative world class leader in drive solutions. With many products that helped shape the landscape of the conventional automotive market, we’re excited to see how we will contribute to the electric field in the near and not-so-near future.