Introducing AI to VCST Reichenbach’s manufacturing flow

28 June, 2024

As the rapid expansion of AI continues to revolutionize various industries, including manufacturing, VCST is no exception. We recognize the potential cutting-edge AI technologies can offer and have started exploring what this could mean for our quality control operations.

AI-Powered Quality Control

To take our quality control a step further, VCST has revolutionized its quality control mechanisms by implementing high-resolution cameras coupled with specialized lighting to achieve the most uniform image of the product possible. These images are then analyzed using traditional vision technology, such as pixel counting and line drawing, in conjunction with AI models. These models are trained to detect deviations from the expected norm, a task that requires precise calibration to distinguish acceptable variations from defects.

Optical Character Recognition (OCR)

Another focus on innovation by VCST is how we use OCR technology to recognize inscriptions on valve blocks, such as supplier text or automated stamping from machines. By using AI for OCR recognition, we have noticed a tremendous improvement compared to more traditional solutions for OCR. Complemented by a new AI based classification tool that ensures the correct product is being processed, a crucial step given the subtle differences between numerous similar products.

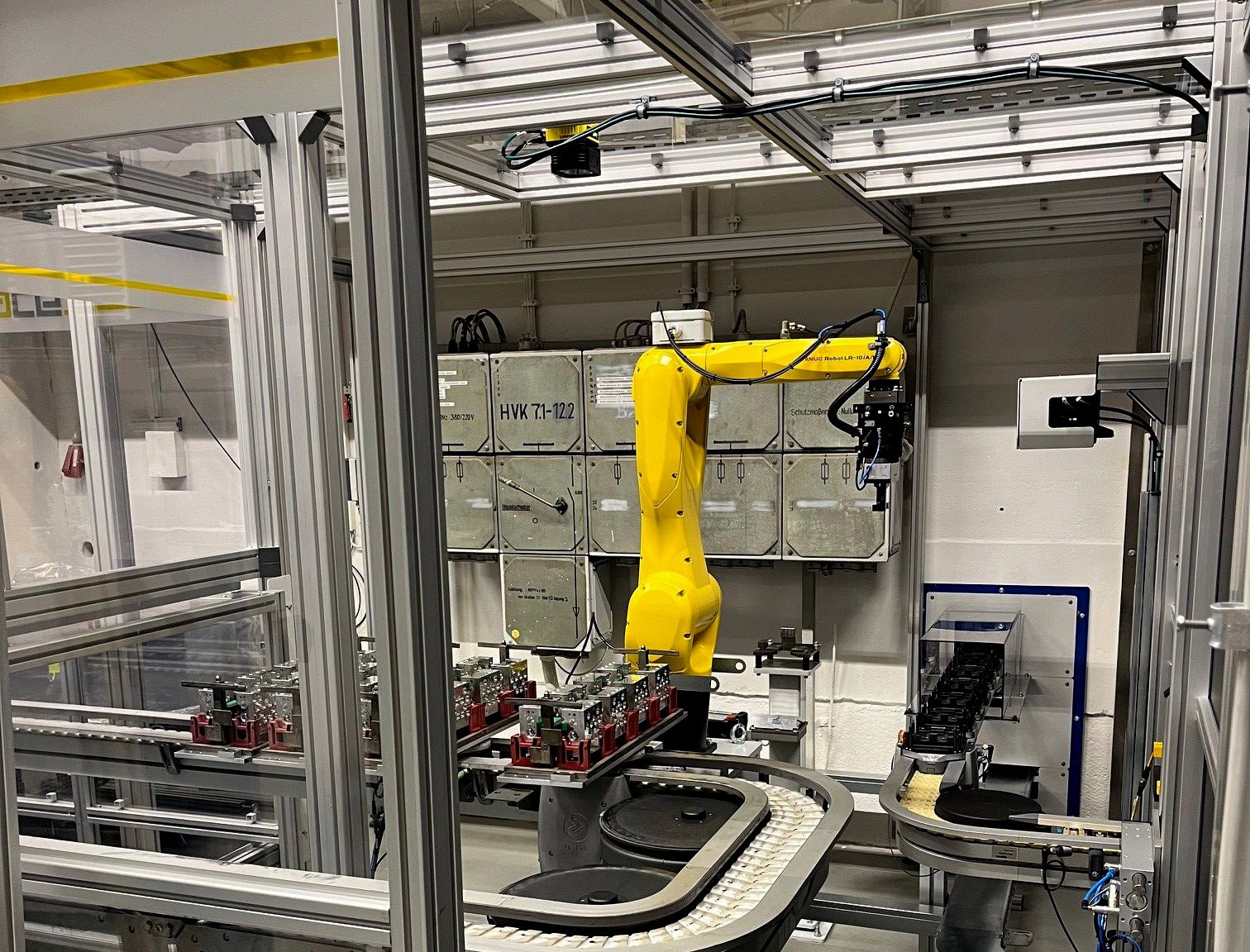

A new dedicated cell

These innovations require a dedicated unit. That is why we have developed a new cell where these AI-driven quality control processes are centralized. VCST Reichenbach is planning to test the cell thoroughly, aiming to improve it to its full capabilities along the way.

Looking ahead, VCST aims to expand these AI-driven solutions to other products beyond our valve blocks. However, this will be a work of long breath, as the challenge lies in the ability to define clear standards for what constitutes a 'good' part in order for the AI system to learn properly what it can indicate as a malfunction. Especially for products like gears that exhibit a wide range of variations.

This system serves as an extra control unit that will ensure the VCST Reichenbach plant to be as efficient and effective as possible when it comes to noticing and preventing deviations in the quality standards for our parts

Even though VCST has only just begun exploring what AI can mean for us in our manufacturing processes, we are extremely excited to see what the future will bring us.